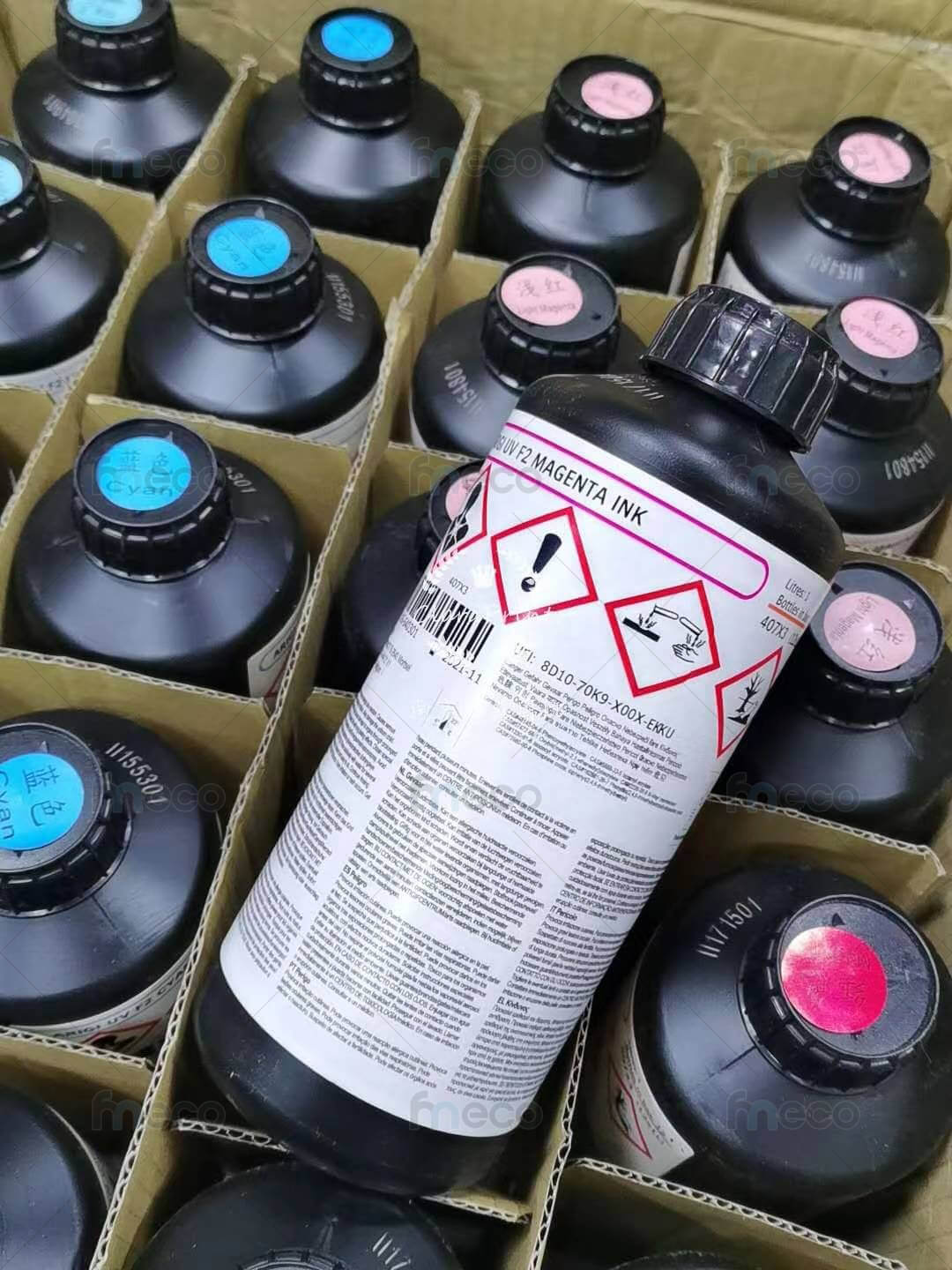

หมึกพิมพ์ Arigi UV Ink สำหรับเครื่องพิมพ์ Dilli Ricoh G5 G6 Konica 1024aSHE 6988H HS2000UV คุณภาพสูง แท้ของยุโรป แสดงสีที่แท้จริงที่สุด

| จำนวน{{focus_pdata.unit}} | ส่วนลดต่อ{{focus_pdata.unit}} | ราคาสุทธิต่อ{{focus_pdata.unit}} |

| {{(typeof focus_pdata.price_list[idx+1] == 'undefined')?('≥ '+price_row.min_quantity):((price_row.min_quantity < (focus_pdata.price_list[idx+1].min_quantity - 1))?(price_row.min_quantity+' - '+(focus_pdata.price_list[idx+1].min_quantity - 1)):price_row.min_quantity)}} | {{number_format(((focus_pdata.price_old === null)?focus_pdata.price:focus_pdata.price_old) - price_row.price,2)}} บาท | {{number_format(price_row.price,2)}} บาท |

| คงเหลือ | ขวด |

| จำนวน (ขวด) |

- +

|

|

ซื้อเลย หยิบลงตะกร้า ซื้อเลย หยิบลงตะกร้า คุณมีสินค้าชิ้นนี้ในตะกร้า 0 ขวด

|

|

|

|

|

| คุยกับร้านค้า | |

| {{ size_chart_name }} |

|

| หมวดหมู่ | หมึกพิมพ์ UV |

| สภาพ | สินค้าใหม่ |

| เพิ่มเติม | |

| สภาพ | สินค้ามือสอง |

| เกรด | |

| สถานะสินค้า | |

| ระยะเวลาจัดเตรียมสินค้า | |

| เข้าร่วมโปรโมชั่น | |

รายละเอียดสินค้า

| ไฮไลท์ |

Dilli DOCAN DLICAN JHF Flora Handtop

Instantly dried by rays of UV light, and thus immediately ready for further handling

Excellent adhesion

Great abrasion and chemical resistance

Super consistency and reliability

No need for evaporation or special layers on substrates

No VOC emissions

|

| ข้อมูล |

น้ำหนัก

บาร์โค้ด

ลงสินค้า

อัพเดทล่าสุด

|

| รายละเอียดสินค้า |

Arigi UV inks are a wide range of multi-pass UV inks for use on wide-format printers (flatbed, hybrid or roll-to-roll). The range consists of inks for rigid and flexible applications developed for printheads supplied by Konica Minolta, Xaar, Ricoh, Seiko, Dimatix and Toshiba Tec, as well as Kyocera (the Arigi UV K-range).

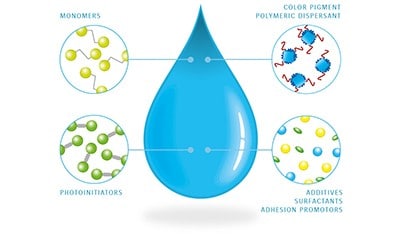

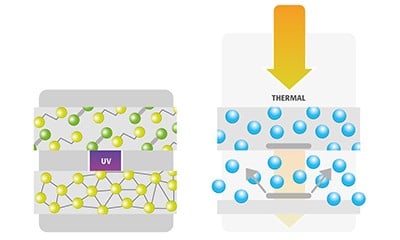

UV inkjet ink compoundsUV inkjet inks comprise the compounds necessary for the photochemical reaction that is started by the exposure to UV light: monomers and photoinitiators. The photoinitiators form radicals upon UV exposure and these in turn start up the polymerization of the monomers. The UV ink derives its color from the pigment dispersion. Many additives are needed to realize all quality aspects, including surfactants, in-can stabilizers, adhesion promoters etc.

UV curing vs. thermal dryingUsing UV light instead of heat, the UV curing process instantly deposits a hardened layer of ink onto the substrate. While conventional heat- and air-drying processes entail solvent evaporation, UV curing does not. Since UV curing also doesn’t generate pollutants or cause coating thickness or volume loss, it results in higher productivity, more resistant results, and less waste and energy use.

1. Lowest ink consumption on the marketAgfa UV (LED) inks are formulated to deliver a wide color gamut with the lowest ink consumption on the market.

2. Consistent from batch to batchOur UV (LED) inks boast outstanding, stable jetting performance–including controlled ink drop formation, great ink latency and long-term jetting reliability. Perfectly tuned to applications, piezo print-heads and print system requirements, Agfa UV (LED) inks deliver identical results over and over again.

3. Longest shelf lifeThanks to their composition and pigment dispersion qualities, Agfa UV (LED) inks are number one when it comes to longevity. When stored under normal conditions, ink can be conserved for up to 24 months, depending on the ink set.

4. Unique ink technologyAgfa UV (LED) inks are designed using highly innovative ink concepts. Our Pigment Shield Technology, for example, is a patented pigment dispersion technology specifically for UV (LED) inks. It guarantees high color strength and ink stability, which also contributes to the ink’s long shelf life. Thanks to our technological know-how, our ink formulations are optimized for lowest ink consumption for every industrial piezo print head. We offer full ink sets, which may comprise high-performing white ink and/or varnish.

5. 100% customer-orientedWhether we are researching, developing, producing or testing our ink formulations, we always prioritize our customers and their needs. Tuned to specific and functional application requirements, Agfa UV (LED) inks offer tailor-made solutions.

|

| เงื่อนไขอื่นๆ |

|

| Tags |

วิธีการชำระเงิน

RELATED ITEMS

RELATED ITEMS

ARTICLE

9 เดือนที่ผ่านมา

1. โทนสีและลักษณะทางสายตา เหลืองเลมอน (Lemon Yellow) เป็นสีเหลืองสดใส สว่าง คล้ายสีของเปลือกมะนาวสุกโทนสีเย็น (มีแนวโน้มไปทางสีเขียวเล็กน้อย)มีความอิ่มตัวของสีสูง (High Saturation) HEX # FFF44F RGB (255, 244, 79) HSL (56.25°, 100%, 65.49%) เหลือง…

4 ปีที่ผ่านมา

หัวพิมพ์อิงค์เจ็ท RicohRicoh มีกลุ่มผลิตภัณฑ์ที่หลากหลาย พร้อมเครื่องมือประเมินผลที่มีประสิทธิภาพ และการสนับสนุนทางเทคนิคที่จำเป็นเพื่อช่วยในการปรับใช้ผลิตภัณฑ์กลุ่มผลิตภัณฑ์ หัวพิมพ์รุ่นไฮเอนด์ที่มีความทนทานสูง รุ่นต่ำสุดที่ออกแบบมาสำหรับการใช้งานระ…

4 ปีที่ผ่านมา

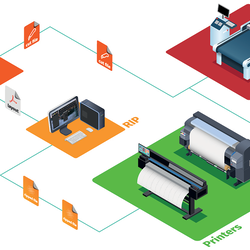

RIP Software (Raster image processing software) คือซอฟต์แวร์ที่ใช้ในการประมวลผลภาพกราฟิกแบบบิทเมพ (Bitmap Graphics)ซึ่งมีโครงสร้างมาจากการจัดเรียงจุดสี (Pixels) ต่อเนื่องกันจนมองเห็นเป็นรูปภาพ โดยภาพประเภทนี้จะได้มาจาก ภาพสแกน ภาพถ่ายจาก กล้องถ่ายรูป…

4 ปีที่ผ่านมา

CalderaRIP เป็นโซลูชัน Workflow ที่สมบูรณ์ ความสามารถในการจัดการขั้นตอนการผลิตทั้งหมดของคุณ ที่ครอบคลุมทั้งระบบ สำหรับการจัดการกระบวนการผลิต การพิมพ์ทางอุตสาหกรรม เทียบกับซอฟต์แวร์ RIP อื่นๆ caldera มีความยืดหยุ่นและประสิทธิภาพที่ดีขึ้น ช่วยให้ผู้ใช้…

4 ปีที่ผ่านมา

1.อายุการใช้งานถอดออกจากเครื่องพิมพ์ขนาดเล็กแบบตั้งโต๊ะ ออกแบบมาสำหรับผู้ใช้ตามบ้านหัวพิมพ์ dx11 xp600เชิงพาณิชย์แท้ของเอปสัน ออกแบบมาสำหรับกลุ่มโรงงานอุตสาหกรรม โครงสร้างอายุการใช้งานภายในและกระบวนการผลิตของหัวพิมพ์อุตสาหกรรมแตกต่างกันออกไป ได้รับกา…

4 ปีที่ผ่านมา

ความแม่นยำในการพิมพ์ในพารามิเตอร์หัวพิมพ์ เพื่อความแม่นยำควรเป็น NPI ไม่ใช่ DPINPI คือความแม่นยำในการพิมพ์ทางกายภาพของหัวพิมพ์ นั่นคือจำนวนรูหัวฉีดต่อนิ้ว เพื่อให้ได้ความแม่นยำที่สูงขึ้นจำเป็นต้องมีหัวพิมพ์มากขึ้นหรือ PASS มากขึ้นDPI คือความละเอียดขอ…

4 ปีที่ผ่านมา

Epson เพิ่งเปิดตัวหัวพิมพ์ I3200 หัวพิมพ์นี้ใช้เทคโนโลยีล่าสุด และเพิ่มหน่วยควบคุมได้มากขึ้น และในขณะเดียวกันก็สามารถรับการสนับสนุนทางเทคนิคจาก Epson หัวพิมพ์ I3200 มีหลายประเภทส่วนใหญ่มีสามรุ่น: I3200-A1, I3200-U1 และ I3200-E1 I ของหัวฉีดซีรีส์ I320…

4 ปีที่ผ่านมา

ตั้งแต่มีเครื่องพิมพ์ UV Flatbed เปิดมิติใหม่ของงานพิมพ์อย่างไม่มีจำกัด ต่อจากนี้ มีโคฯ จะกล่าวถึงฬาที่กำลังฮิตฮอต ความเท่ห์ "สเกตบอร์ด" ส่วนใหญ่ของผู้ที่ชื่นชอบสเกตบอร์ดเพลิดเพลินกับความรู้สึกของเท้าลอยจากพื้น อีกทั้งยังลวดลายโดดเด่น สีสดสะดุดตาพร้อ…

MecoInkjet Printer Supplies จัดหาเครื่องจักรและอุปกรณ์อุตสาหกรรม Printing Solution

MecoInkjet Printer Supplies จัดหาเครื่องจักรและอุปกรณ์อุตสาหกรรม Printing Solution

อีเมล : mecoinkjet@gmail.com

TOP เลื่อนขึ้นบนสุด

SEARCH

CATEGORY

MEMBER

- ระดับ{{userdata.dropship_level_name}}

- ไปหน้าหลักตัวแทน

- ทั้งหมด {{(order_nums && order_nums.all)?'('+order_nums.all+')':''}}

- รอการชำระเงิน {{(order_nums && order_nums.wait_payment)?'('+order_nums.wait_payment+')':''}}

- รอตรวจสอบยอดเงิน {{(order_nums && order_nums.wait_payment_verify)?'('+order_nums.wait_payment_verify+')':''}}

- รอจัดส่งสินค้า {{(order_nums && order_nums.wait_send)?'('+order_nums.wait_send+')':''}}

- รอยืนยันได้รับสินค้า {{(order_nums && (order_nums.wait_receive || order_nums.wait_confirm))?'('+(order_nums.wait_receive+order_nums.wait_confirm)+')':''}}

- รอตรวจสอบข้อร้องเรียน {{(order_nums && order_nums.dispute)?'('+order_nums.dispute+')':''}}

- เรียบร้อยแล้ว {{(order_nums && order_nums.completed)?'('+order_nums.completed+')':''}}

- ทั้งหมด {{(order_nums && order_nums.all)?'('+order_nums.all+')':''}}

- รอการชำระเงิน {{(order_nums && order_nums.wait_payment)?'('+order_nums.wait_payment+')':''}}

- รอตรวจสอบยอดเงิน{{(order_nums && order_nums.wait_payment_verify)?'('+order_nums.wait_payment_verify+')':''}}

- รอจัดส่งสินค้า {{(order_nums && order_nums.wait_send)?'('+order_nums.wait_send+')':''}}

- ส่งสินค้าเรียบร้อยแล้ว {{(order_nums && order_nums.sent)?'('+order_nums.sent+')':''}}

CONTACT US

|

Check Page Rank of your Web site pages instantly: |

|

This page rank checking tool is powered by PRChecker.info service |